Quantity

Price

Total price

1

$28.1820

$28.1820

10

$26.2395

$262.3950

25

$25.9560

$648.9000

40

$25.3155

$1,012.6200

80

$22.2285

$1,778.2800

230

$21.4725

$4,938.6750

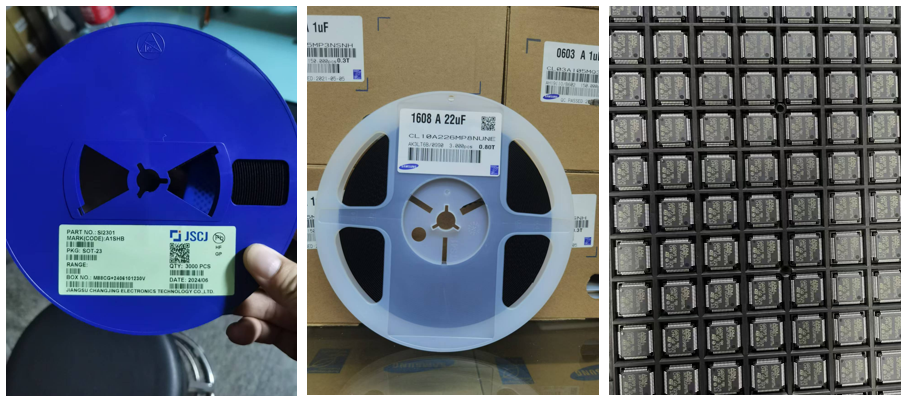

| TYPE | DESCRIPTION |

| Mfr | ATP Electronics, Inc. |

| Series | Industrial |

| Package | Tray |

| Product Status | ACTIVE |

| Package / Case | 153-FBGA |

| Mounting Type | Surface Mount |

| Memory Size | 256Gbit |

| Memory Type | Non-Volatile |

| Operating Temperature | -40°C ~ 85°C |

| Technology | FLASH - NAND (MLC) |

| Memory Format | FLASH |

| Supplier Device Package | 153-BGA (11.5x13) |

| Memory Interface | eMMC |

| Memory Organization | 32G x 8 |

| DigiKey Programmable | Not Verified |